Professional commercial steel structure poultry farming shed chicken house

Product Description

Product Application

The structure of customized poultry farm are flexible because different customers need different style. We help the customer design the structure to meet the individual requirements. We provide free design for you. Of course, we can follow your drawings to arrange. Our fireproof prefabricated wall battery prefab light steel hen house has many features. Low cost small prices, standardization, modular combination design, factory production, removable mobile, reusable, easy to stock restructuring, safe, environmental protection, beautiful and efficient light steel system integration house.

1. Frame

High humidity and more ammonia can easily lead to some of the facilities corrosion. So we use galvanized H beam for columns and beams. We also use galvanized C beam for purlin. The galvanized frame can protect from being corroded thus can extend the life of the structure. Poultry shed in coastal city demand building have good wind resistance. We can design by the advanced software.

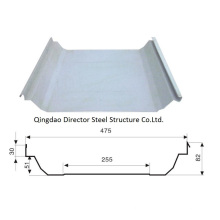

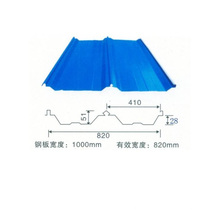

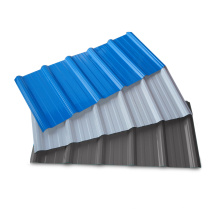

2. Panel

Depending on the climate in different regions, you can choose veneer or insulation composite panel. The plates have a variety of options colors. The board of tile can have a wide selection. Sandwich Panels have EPS, glass fiber, rock wool. The panel can be heat insulation and prevent rust and corrosion. If you don't want to use the panel, you can use the wire mesh for wall. In hot or cold areas, we recommend to use composite panels, thermal insulation and heat insulation. Of course, the veneer price will be lower.

3 .Height

Generally, if the poultry farm is free range farming, the height is 2m-3.5m. If it is cage farming, the height should be determined according to the number of cage layers.

4. Production time, installation time

About 3,000 square meters of the poultry shed, from design to sourcing to production finally ended is about a month.

5 .Provide various types of ancillary farming equipment

Main Steel Frame | Column | Q235, Q355 Welded H Section Steel |

Beam | Q235, Q355 Welded H Section Steel | |

Anchor Bolt,High Strength Bolt | M20,M24 | |

Secondary Frame | Purlin | Q235 C and Z purlin |

Knee brace | Q235 Angle Steel | |

Tie Rod | Q235 Circular Steel Pipe | |

Bracing | Brace | Q235 Round Bar |

Vertical and Horizontal Support | Q235 Angle Steel, Round Bar or Steel Pipe | |

Maintenance system | Roof Panel | |

Wall Panel | Sandwich Panel / Corrugated Steel Sheet | |

Door | Sliding Sandwich Panel Door / Rolling Metal Door / Personal Door |

Main Features

1. Wide span: single span or multiple spans, the max span is 36m without middle column.

2. Low cost and maintenance: unit price range from USD35/m2 to USD70/m2 according to customers request.

3. Fast construction and easy installation: time saving and labor saving.

4. Long using lifespan: up to 50 years.

5. Nice appearance.

6. Others: environmental protection, stable structure, High quake-proof, water proof and fire proof, and energy conserving.

Pre-Sales Service

* Inquiry and consulting support.

* Scheme drawing, 3 d impression drawing.

* Visit our Factory.

After-Sales Service

* design: construction drawings, shop drawings, installation drawings available

* fabrication: we could fabricate all kinds of Steel Structure elements in time and with high quality

* installation: At the request of the customer, we could send one or two engineer to guide installation, or a small team to install at the same time teaching the local workers to install , or enough workers to install all the goods by ourselves.That depends on whether the cost is economical.

Packaging | ||

Size | no longer than 11.8m | |

Weight | 10~28 tons in each container | |

Packaging Details | The heavy elements: loaded in 40ft OT or loaded in 40HC,40GP or 20GP with steel pallet by crane and forklift. The light elements: loaded in 40HC, 40GP or 20GP by hands. Small parts: in bags or boxes in case lost All the elements should be fixed or stable in the containers in case scratch or broken.. | |

In Bulk Cargo Ship | ||

Size | no longer than 26m | |

Weight | no limitation | |

Packaging Details | The goods should be fixed with pallets. The pallets should be strong enough in case excessive pressure. | |

1.What kind of company you are?

We are Steel Structure Building Manufacturer located in Qingdao China, We were gaining good reputation among our customers for our professional, warm and thoughtful service. Because we know that a long terms business based on the quality control, price, packing, delivery time etc.

2. Does your company is a factory or trade company?

We are factory, so you will enjoy the best price and competitive price. Our factory covers an area of 80,000 square meters.

3. Whats the quality assurance you provided and how do you control quality ?

Established a procedure to check products at all stages of the manufacturing process - raw materials, in process materials, validated or tested materials, finished goods, etc.

4. Can you offer designing service?

Yes, we have more than 20 design engineers. We could design full solution drawings as per your requirements. They use software: Auto CAD,PKPM, MTS, 3D3S, Tarch, Tekla Structures(Xsteel)V12.0.etc.

5. Do you offer guiding installation on site overseas?

Yes, we can provide the service of installation, supervision and training by extra. We can send our professional technical engineer to supervise installation on site overseas. Besides, We also have our own abroad installation team consisting of more than 30 people.

They have succeeded finishing many projects in different countries, such as Iraq, Dubai, South Africa, Algerial, Ghana, Gabon, Tajikistan, Burkina Faso, Panama, Australia.

6. What conditions do you need to start a design and quotation?

a. Location (where will be built? ) _____country, area

b. Size: Length*width*height _____mm*_____mm*_____mm

c. Live load on roof(KN/M2), live load on second floor(KN/M2) if have

d. Wind load (max. Wind speed) _____kn/m2, _____km/h, _____m/s

e. Snow load (max. Snow height) _____kn/m2, _____mm

f. Anti-earthquake _____level

g. Brickwall needed or not If yes, 1.2m high or 1.5m high

h. Thermal insulation If yes, EPS, fiberglass wool, rockwool, PU sandwich panels, Corrugated steel sheet with fiber glass wool will be suggested; If not, the Corrugated steel sheet will be ok. The cost of the latter will be much lower than that of the former.

j. Door quantity & size _____units, _____(width)mm*_____(height)mm

k. Window quanity & size _____units, _____(width)mm*_____(height)mm

l. Crane needed or not If yes, _____units, max. Lifting weight____tons; Max. Lifting height _____m

m. Skylight belt, ventilator and any other accessories if needed.

Product Categories : Steel Poultry House

Premium Related Products